- 描述

- Inquiry

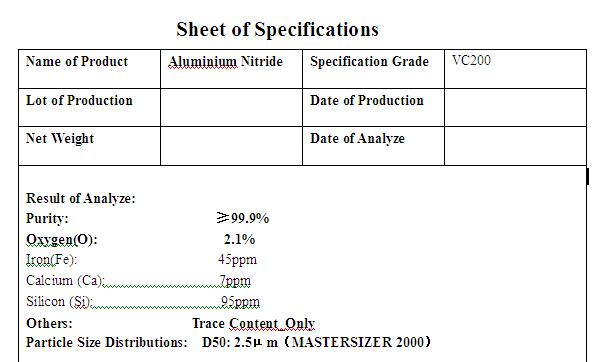

Micron Grade

Basic Features: Aluminum nitride ceramic powder is a ceramic material with high thermal conductivity and excellent electrical insulation. Aluminum nitride powder produced by a promise material has high purity, small particle size, uniform distribution, large specific surface area, high surface activity, Low bulk density, good dispersibility and injection molding performance. It can be used in composite materials, has good compatibility with semiconductor silicon and good interfacial compatibility. It can improve the mechanical properties and thermal conductivity of composite materials.

The main application:

1) High thermal conductivity filler for thermal paste, thermal grease;

2) for high thermal conductivity of thermal plastic, thermal silica film, epoxy thermal conductive potting filler;

3) High thermal conductive filler for thermal engineering plastics;

4) for fixing film, polyimide film high thermal conductivity filler;

5) High thermal conductivity filler for packaging materials, high temperature lubricants, adhesives, thermal paint, thermal ink;

6) Insulation and thermal conductive filler for manufacturing high thermal conductivity integrated circuit board (MCPCB, FCCL)

7) High thermal conductivity filler for thermal interface material (TIM);

8) for crucible metal smelting, evaporation boat, ceramic cutting tools, cutting tools, microwave dielectric materials;

9) for the manufacture of high thermal conductivity of aluminum nitride ceramic substrate, aluminum nitride target, and various ceramic products;

10) for conductive ceramic evaporation boat, with titanium diboride, boron nitride and other materials composite;

11) for the synthesis of high-quality LED phosphors.

Nano grade

Average particle size: 40nm

Purity: 99.9%

Specific surface area: 70m2/g

Volume density: 0.15g/cm3

Crystal: hexagonal

Color: off-white

Product features

The product has high purity, small particle size, large specific surface area and high surface activity. The oxygen content of the powder treated by surface packaging is very low (<0.1%), and the insulation thermal conductivity effect is very obvious.

Application field

1. Manufacturing integrated substrate, electronics, optics, radiator, high temperature crucible preparation of metal matrix and polymer matrix composites, especially in high temperature sealing adhesive and improve the cooling performance of the material in the electronic packaging materials and strength characteristics, have very good application prospect, can replace the imported micron aluminum nitride;

2. Thermal conductivity silica gel and thermal conductivity epoxy resin: ultra-high thermal conductivity silica gel prepared by nano aluminum nitride has good thermal conductivity, good super electrical insulation, wide electrical insulation and service temperature (working temperature 80-250℃), lower consistency and good construction performance. Products have reached or exceeded imported products, because can replace similar imported products and widely used in electronic devices heat transfer medium, improve work efficiency. Such as CPU and radiator gap, high-power audion, thyristor element, diode, and the substrate contact with the thin seam of the heat transfer medium. Nanometer thermal conductivity paste is to fill the gap between IC or transistor and heat sink, increase the contact area between them, and achieve better heat dissipation effect;

3. Nanometer lubricating oil and antiwear agent, nanometer ceramic oil added in the modified aluminum nitride ceramic nanoparticles as lubricating oil on the engine internal friction pair of metal surface, under the action of high temperature and extreme pressure is activated, and strong permeability embedded in the metal surface dent and microporous, repair the damaged surface and form nano ceramic coating. Because of the membrane separation effect, make the effects of the friction is relative motion between the parts in this layer of protective film, nano ceramic particles like small ball will be part of the friction between the friction pair by traditional sliding friction into rolling friction, thereby greatly reducing the friction, the friction between moving parts dropped to near zero, the engine super anti-wear protection effect, by improving the lubrication, can decrease the friction coefficient of more than 80%, improve the antiwear ability by more than 350%, reduce wear and tear more than 80%, more than 3 times to extend the service life of machine parts, reduce downtime and reduce maintenance costs, prolong overhaul period more than double, Energy saving 10%-30%, increase the output power of the equipment 20%-40%, the addition amount is only 200%-1/1000;

4. Application of high thermal conductivity plastics: modified nano aluminum nitride powder can greatly improve the thermal conductivity of plastics. By adding 1% of the experimental products to the plastic, the thermal conductivity of the plastic can be increased from 0.3 to 3, and the thermal conductivity has been increased by more than 10 times. At present, it is mainly used in PVC plastic, polyurethane plastic, PA plastic, functional plastic, etc.

5. Other applications: nano aluminum nitride can be used in crucible melting non-ferrous metal and semiconductor material gallium arsenide, evaporation vessel, thermocouple protection tube, high temperature insulation, microwave dielectric material, high temperature and corrosion resistant structure ceramics and transparent aluminum nitride microwave ceramic products

相关产品

-

Manganese ferrite

Other name: Manganese Ferrite Black ,manganese ferrite black spinel

CAS no. : 68186-94-7

EINECS no. : 269-056-3

Molecular formula: MnFe2O4

Molecular weight: 230.63

-

Lithium iron phosphate

English name: Lithium iron phosphate carbon coated

Alias: Ferrous lithium phosphate, NP 1; NP 1 (phosphate); PT 30; PT 30 (phosphate); Phos-Dev 21B, Lithium iron phosphate

Molecular formula: LiFePO4

Molecular weight: 157.76

CAS NO .: 15365-14-7

-

Stannic Sulfide

Other name: tin monosulfide, tin(ii) sulfide, Tin sulphide; thioxostannane

Chemical formula: SnS

Molecular weight:150.775

CAS number: 1314-95-0

EINECS: 215-248-7

Melting point : 880 ℃

Boiling point: 1230 ℃

Water: insolubility

Density: relative density 5.22

Molality: 150.775 g/mol g·mol⁻¹

-

Cuprous telluride

Other name: dicopper telluride, Cuprous monotelluride;

CAS no. : 12019-52-2

EINECS no. : 234-646-1

Molecular formula: Cu2Te

Molecular weight: 254.692

Density: 7.27g /cm3

Melting point: 900 ℃ -

Zinc telluride

Other name: tellanylidenezinc

CAS no. : 1315-11-3

EINECS no. : 215-260-2

Formula: TeZn.

Molecular weight: 193.009

Melting point is 1238.5 ℃

Density: 6.34 g/Ml at 25 ℃

-

Osmium Tetroxide

Other name: Osmium(VIII) oxide; tetraoxoosmium; Osmium oxide

CAS no. : 20816-12-0

EINECS no. : 244-058-7

Molecular formula: O4Os

Molecular weight: 254.2276

Melting point (℃) : 41.0

Relative density (water =1) : 4.91

Boiling point (℃) : 130

Saturated vapor pressure (kPa) : 0.93/20 ℃

-

Nano nickel oxide

English alias: Nickel sesquioxide; Nickelic oxide; Nickel peroxide; Nickel oxide (Ⅲ)

The CAS number: 1314-06-3

EINECS no. : 215-217-8

Molecular formula: Ni2O3

Molecular weight: 165.38

-

Nanometer Tin oxide

English alias: Tin (IV) oxide; Tin Dioxide;

CAS no. : 18282-10-5; 1332-29-2

EINECS no. : 242-159-0; 215-569-2

Formula: SnO2

Molecular weight: 150.69

Density: 6.95

Melting point: 1127 ℃

Solubility: INSOLUBLE

-

Copper zinc tin sulfide

Other name: CZTS

Chemical formula: Cu2ZnSnS4

Molecular weight :439.471 g / mol

CAS Number:12158-89-3

Melting point: 990 ° C (1,810 ° F; 1,260 K)

Safety Description: Non-toxic

-

Nickel cobalt manganese